When we forayed into the palm oil sector in 2012, we found palm oil farmers were losing about 50% of their available fresh fruit bunches (FFB) for processing due to shortage of and high cost of hiring climbers who face serious health and safety hazards from climbing the palm trees. This also meant mill owners could not find adequate quantities of FFBs they needed to keep their mills in operation all year-round, leading to months of idleness at the mills with no income for the mill owners.

Likewise, we found that millers, also known as processors, were not getting the maximum quantity of oil they could get from the limited supply of FFBs because they had no access to appropriate processing technologies so they were using labor intensive manual processing methods.

We began working to create a market for efficient technologies for the farmers and to increase awareness of farmers, processors and mill owners on the availability and benefits of these technologies.

The technologies included the Mechanical Adjustable Harvester (MAH) and Malaysian Knife (MK) for harvesting palm fruits with significantly less risk of injury – compared to traditional tree climbing and the small scale processing equipment (SSPE) that reduces drudgery of milling time for 1 ton of palm oil from 6-7 hours to just under 1 hour and produces better quantity and more valuable palm oil.

Using a combination of engagements, market demonstrations and value propositions, we attracted 20 agro dealers who expanded their product offerings by investing in the sale and servicing of the harvesting technologies and trained 37 local fabricators who currently make a living from manufacturing and selling the improved processing machine to processors and millers – and they do this without PIND’s involvement as it has become a business for them.

Despite making the efficient technologies available, palm oil farmers and processors could not afford to buy the MAHs and the MAs while the mill owners could not afford to buy the improved processing mills.

Access to finance remained a huge challenge to the adoption. To provide incentives to further strengthen this very important support market for processors for the region, PIND introduced a technology adoption grant support system that gives the fabricators access to 50% of the production and installation cost of the machines once the millers make a down payment of 50% to demonstrate demand for the machine. In addition, we facilitated access to loans worth N1, 000,000 for four (4) farmer associations to purchase the harvesting technologies which they in turn rent to their members.

All through 2017, these support market actors catalyzed by PIND organized series of workshops, demonstrations and seminars across the Niger Delta to promote the Mechanical Adjustable Harvester (MAH) and Malaysian Knife (MK) for more efficient harvesting of palm fruits; and the use of small scale processing equipment (SSPE) for increased efficiency in processing palm oil to farmers which led to increased demand for them, with a cumulative total of 74 SSPEs, 155 MKs and 57 MAHs sold and in use by the end of the year across all the States of the Niger Delta. The adopters include local climbers who also began to use the harvesting technologies instead of climbing the trees – a shift that is expected to reduce their health hazards.

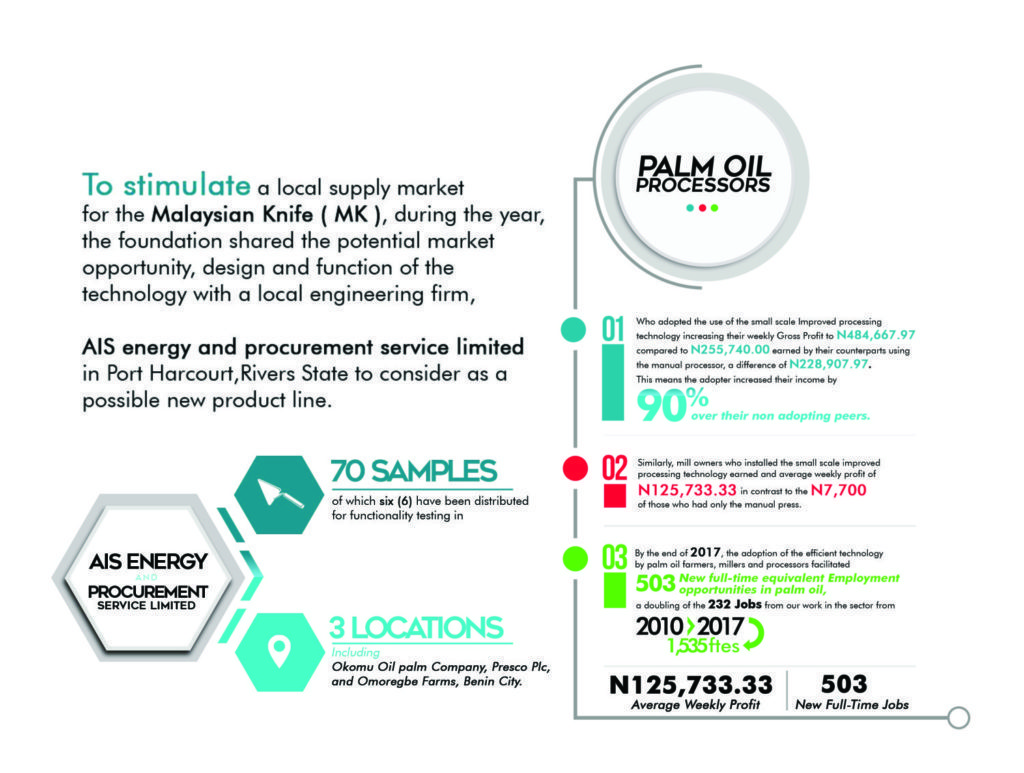

Palm oil processors who adopted the use of the small scale improved processing technology increased their weekly gross profit to N484,667.97 compared to the N255,760.00 earned by their counterparts using the manual press processor, a difference of N228,907.97. This means the adopters increased their weekly income by 90% over their non-adopting peers. Similarly, mill owners who installed the small scale improved processing technology earned an average weekly profit of N125.733.33 in contrast to the N7, 700 of those who had only the manual press.

By the end of 2017, the adoption of the efficient technologies by palm oil farmers, millers and processors facilitated 503 new full-time equivalent employment opportunities in palm oil, a doubling of the 232 jobs in 2016, bringing the total new jobs from our work in the sector from 2010 -2017 to 1,535 FTEs.

To stimulate a local supply market for the Malaysian Knife (MK), during the year, the Foundation shared the potential market opportunity, design and function of the technology with a local engineering firm, AIS Energy and Procurement Service Limited in Port Harcourt, Rivers State to consider as a possible new product line. AIS produced over 70 samples of which six (6) have been distributed for functionality testing in 3 locations, including Okomu Oil Palm Company, Presco Plc, and Omoregbe Farms, Benin City.

Lead Farmers and Input Companies Promoted Best Management Practices: Still on palm oil, lack of access to information on good agronomic practices and inputs for better yield and poor access to quality seedlings were serious constraints to the productivity of palm oil farmers. We inspired input companies, who are very important support market actors, to showcase to farmers good farming practices that will lead to increased yields from their oil palm farms through a Best Management Practices (BMPs) partnership intervention.

Demonstration farms were set up to serve as learning laboratories run by trained lead farmers who model improved farming practices for other farmers to copy. When 2017 ended, the partnership had set up 28 BMP demo farms in Ondo, Edo, Delta, Rivers, Cross Rivers and Akwa Ibom. The input companies trained 207 lead farmers in addition to 112 in 2016, making a total of 319 trained BMP Lead Farmers in the region. They have in turn spread the knowledge to another 4,620 farmers.

One hundred and ninety five (195) Lead Farmers who adopted the best practices in the last two years to one and half years saw increased yield by four tons per hectare which gave each farmer N407,500 extra income from two and half hectares of plantations. In addition, the adoption of best practices resulted in the reduction of farmers’ cost of managing their farms by 20 percent that translates to a saving of N107, 925 on maintenance cost for two and half hectares.

Adoption of Best Management Practices (BMPs) for oil palm plantation has deepened in the Niger Delta, so palm oil farmers are increasing Income at lower cost.

We also understood that good agronomic practices without access to high yielding seeds would limit the productivity potentials in the palm oil sector. So we engaged with Okomu Oil Palm Company, a large plantation market actor with access to high yielding seeds that can produce over 25 tons per hectare to start an access to quality seedlings intervention to address the challenges farmers face accessing viable oil palm seedlings in the Niger Delta. The model is to identify, train and certify seedling distributors across the Niger Delta, thereby creating an effective distribution network. Five community-based seedling distributors were selected as partners in 2017.

Okomu then trained 10 nursery operators from Akwa Ibom, Cross River, Delta, Edo, Imo and Ondo States on best practices in handling seeds at pre-nursery and nursery settings, after they paid 70 percent of the cost of seeds they intended to buy upfront, indicating the viability of market for the seedlings that is crucial for the business sustainability.

Following this, Okomu ordered 60,000 sprouted nuts which were raised by the seedling distributors in their various locations and distributed to farmers at a fair and affordable rate, creating a sustainable market for the seedlings between a major plantation, seed distributors, nursery operators and palm oil farmers – all through PIND’s facilitation. Through this business model, smallholder farmers gained access to 50,000 seedlings raised by trained nursery operators in the Niger Delta.

In palm oil, PIND’s work to improve farmers’ agronomic practices, increase their access to efficient technologies and improve farmers’ access to quality seedlings through seminars, trainings and workshops for palm oil farmers, processors and equipment fabricators led by its catalyzed support market actors – agro dealers, fabricators, input companies, lead farmers and plantation companies – reached 7,305 participants (2,416 females, 4,889 males in 2017, making a cumulative reach of over 17,000 participants (5,339 females, 12,456 males) and leveraged N63,250,000, a significant increase compared to N26,600,000 in 2016. So far, we have leveraged over N100 million in investments.

Working through these market actors, we have trained 8,138 farmers (1,627 females) on Best Management Practices (BMP) from 2010 – 2017 to improve their agronomic practices on field access, ground cover management, herbicide application, fertilizer application, pruning, canopy management, harvesting, yield taking, records keeping, and work rate systems.

The improvements in agronomic practices and access to efficient technologies have helped improve the net additional income of 6,526 beneficiaries in the sector to over N1 billion by the year end.

DOWNLOAD REPORT HERE